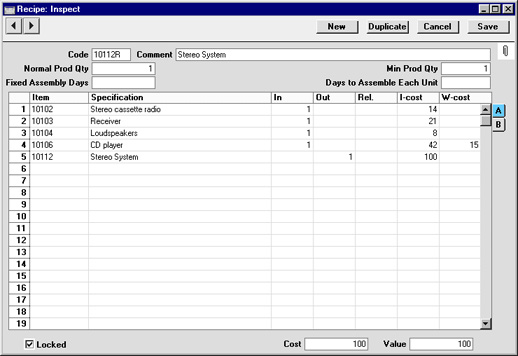

Introduction to the Recipe Register

Assembled Items are built by your company from other Items (i.e. from components). This assembly process is governed by Recipes.

Before entering a Recipe, the result of the Recipe (the assembled Item) should be entered to the Item register as described here. Specify a Recipe for this Item on the 'Recipe' card. The Recipe should then be defined using the Recipe register.

If the assembled Item is entered as a Structured Item using the options on the 'Pricing' card of the Item record, the Recipe will be applied at the moment of delivery. The Item Code of the assembled Item is entered to the Order. When it is delivered, the stock levels for each of the components will be reduced according to the Recipe.

If the assembled Item is entered as a Stocked Item, it must be built prior to delivery using the Production register and held in stock. When the Production record is marked as Finished, stock levels for the components will be decreased according to the Recipe and those for the assembled Item increased.

In defining Recipes, ensure you use the same Recipe Code that you entered on the 'Recipe' card of the Item record. In the Production module, click the [Recipes] button in the Master Control panel or select 'Recipes' from the Registers menu. Click the [New] button in the Button Bar to create a new Recipe record.

- Code

- The Code for the Recipe can be up to 20 characters long. It is recommended that the Code used is similar to the Item Code of the assembled Item.

- Comment

- A description of the assembly.

- Normal Prod Qty

- This field is only used if the result of the Recipe is a Stocked Item. If this is the case, specify here how many times the Recipe is to be used in a single Production record. For example, if the output quantity of the Recipe is two (entered on the last row of the grid) and it is applied five times in a Production record (i.e. this field has been set to five), the result will be ten units of the output Item being added to stock.

- This field should be set to one if the output Item or any of the components are serial numbered at unit level.

- Min Prod Qty

- This field is only used if the result of the Recipe is a Stocked Item. It is the minimum number of applications of the Recipe in a single record in the Production register.

- Fixed Assembly Days, Days to Assemble Each Unit

- These fields are only used if the result of the Recipe is a Stocked Item. The Days to Assemble Each Unit is the time required to build a single Item (i.e. it is for work that is carried out once per unit built, many times per production run). The Fixed Assembly Days is a constant figure irrespective of the quantity being built (i.e. it is for work that is carried out once per production run).

- For example, the Recipe might represent the assembly of an Item from moulded plastic components. The time taken to retrieve the set of moulds from the store, order the raw materials and set up the assembly line is the same irrespective of the quantity being built. This time is entered to the Fixed Assembly Days field. The remainder of the production time is taken up by pouring the plastic into the moulds, letting it cool, assembling the components and packaging them. If there is only one set of moulds, this can only be done for one unit at a time and therefore this time is entered to the Days to Assemble Each Unit field.

- This information will be used by the 'Create Planned Records' Maintenance function in the Sales Orders module. This function creates Productions whose dates are calculated from the Planned Delivery Date of Sales Orders and these lead times from the appropriate Recipes. This ensures Productions for Items on Sales Orders are raised as late as possible, so that the goods are built just before they are scheduled for delivery to the Customer. Any necessary Purchase Orders for the components will also be created. These will be dated using the Delivery Days from the Default Purchase Item for the components, ensuring they arrive in time for the assembly process to be completed.

Use the grid area that takes up most of the screen to list the input Items (i.e. the components that will be used to build the final assembly). On the last row of the grid, enter the Item Number of the assembly or the finished product (i.e. the result of the Recipe). This must be a

Structured Item or a

Stocked Item. If the

Production register will be used to build the Item, or if the result of the Recipe will itself be used as a component in another Recipe, it must be a

Stocked Item. A Recipe can result in more than one assembly or finished product: if so, they should all be the same Type (i.e. all

Structured Items or all

Stocked Items), and they should be listed in the grid after the components.

Flip A

- Item

- Paste Special

Item register

- Enter the Item Number of each component Item. On the final row, enter the Item Number of the finished product.

- Specification

- Hansa fills in the Item Name.

- In

- Enter the quantity of each component required to make or build the finished product. Do not enter any inputs for the assembly on the last line.

- Separate rows each with a quantity of one should be used for multiple quantities of Items which carry serial numbers at unit level.

- In any Nominal Ledger Transactions arising from Production records using this Recipe, the credit amount will be taken from the rows with an In quantity (i.e. input Items).

- Out

- This field contains the quantity of assembled Items that can be made from the components listed above. Usually, this will be just one, and it must be one if the Recipe relates to an Item.

- In any Nominal Ledger Transactions arising from Production records using this Recipe, the debit amount will be taken from the rows with an Out quantity (i.e. output Items).

- Rel.

- Relativity. This field is only used if the result of the Recipe is that more than one Item will be assembled (i.e. with different Item Numbers). In each row representing an output Item, enter a percentage figure. When the FIFO input cost of each Production record is calculated, the total cost of the components will be distributed according to the percentages entered here.

- I-cost

- Input cost value (per unit). If the row contains an input Item, enter the unit Cost Price for the Item. A default value will be brought in from the Item. The cost shown in this field is NOT the same as the FIFO stock value. This cost can be updated using the 'Update Recipe' Maintenance function.

- If the row contains an output Item (i.e. the assembled Item), enter the cost value of that Item. This will usually be the sum of the Cost Prices of the input Items, taking quantities into account.

- The total input costs are shown in the Cost field below.

- W-cost

- Work cost value (per unit). Enter a work cost for inputs and/or outputs. Usually, this will be cost of the labour required to build the assembled Item. Work cost values are added to the Cost and shown in the Value field below.

- Note that in the sample illustration above the work cost has been defined using one of the rows featuring an input Item. This ensures the work cost will correctly be included in the credit amount in any Nominal Ledger Transaction arising from Production records using this Recipe.

Flip B

- Description

- Any notes about the Item can be recorded here.

- Recipe

- This field shows whether the Item is an assembly (i.e. it is one with a Recipe specified on its 'Recipe' card. This is updated automatically by Hansa and can't be changed.

Footer

- Locked

- Once you are certain the Recipe is correct, you should check this box to prevent further changes. Once a Recipe has been used in a transaction (e.g. Delivery or Production), it should not be changed because doing so may introduce inaccuracies into the stock records.

- If it subsequently becomes necessary to change a Recipe, you should not do so. Instead you should create a new one (and attach it to a new Stocked or Structured Item).

! | Do not change a Recipe once it has been used in a stock transaction. |

|

- Cost

- This field contains the sum of the input costs.

- Value

- This field contains the sum of the input costs and the work costs. This value must be transferred manually to the Cost Price field on the 'Costs' card of the Item record for the assembled Item.