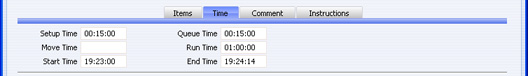

Entering a Production Operation - Time Card

- Setup Time, Queue Time, Move Time, Run Time

- Default taken from

Routing row or Standard Operation

- Use these four fields to stipulate the time required for the Operation, as follows:

- Setup

- the time required to set up the Machine or otherwise prepare for the Operation e.g. calibration or replenishing fluids or consumables.

- Queue

- the time required to wait for parts to be ready from the previous Operation e.g. waiting for paint to dry or heated parts to cool. Queue time is also known as "non-instant availability".

- Move

- the time required to move parts from stock or from the previous Operation.

- Run Time

- the time required for the Operation itself.

These are the times required for the entire Standard Operation, not to produce one unit. They will be copied from the relevant Routing row.

- If you are using the Fixed Time option in the Production Settings setting, the 'Items' card of each Production Operation will contain extra rows for each type of Time. The Item Numbers in these rows will be the Setup, Queue, Move and Labour Cost Items specified in the Production Settings setting, and the Unit Cost in each case will be the Work Cost per Hour in the same setting. The In Qty in each of these rows (number of hours) will be the times specified in the relevant Routing row or Standard Operation. These extra rows allow you to account for the running costs of the Operation.

- The times specified in the relevant Routing row or Standard Operation will also be copied to these fields. The times shown here are for information only: if you need to make a change that you want to be reflected in the posting to the Work Cost Account, make that change in the relevant row.

- If you are using the Actual Time option in the Production Settings setting, you can still specify times here. In this case, these times will not be used to account for the running costs of the Operation, but you can use them as guides, to give an idea of how much time is required for the Operation.

- Start Time

- Paste Special

Current Time

- The time when the work represented by the Production Operation record began. If this field is empty, the current time will be placed here automatically when you mark a Production Operation as Started and save it.

- You can use this Start Time to calculate the running cost of the Actual Machine used in the Production Operation: please refer to the description of the Actual Machine field here for details.

- If you have used the Time options in the Production Settings setting to choose that you will record Actual Time against Production Operations, you will record that time using Activities. It is recommended you specify Start and End Dates and Times before creating an Activity from an Operation, as they will be transferred to the Activity. This will help ensure time recording and the recording of costs associated with that time in the Nominal Ledger are both accurate.

- End Time

- Paste Special

Current Time

- The time when the work represented by the Production Operation record finished. If this field is empty, the current time will be placed here automatically when you mark a Production Operation as Finished and save it.

- You can use this End Time to calculate the running cost of the Actual Machine used in the Production Operation: please refer to the description of the Actual Machine field here for details.

---

In this chapter:

See also:

Go back to: