Batch Quality Control Rules

This page describes the Batch Quality Control Rules setting in the Service Orders module.

---

If you need to control the sale of an Item/Serial Number using quality control tests, you should first list the tests that can be carried out by the quality control department in the Batch Quality Control Tests setting. You can then gather the Tests together in groups, using the Batch Quality Control Templates setting. Finally, you should assign a group of Tests to each Item, using the Batch Quality Control Rules setting. You can assign more than one Template to a particular Item, to be used in different circumstances. For example, you may need to carry out different sets of Tests when receiving an Item into stock for the first time and when receiving an Item back into stock that has been returned by a Customer. You can also specify that different sets of Test will be carried out depending on the Location.

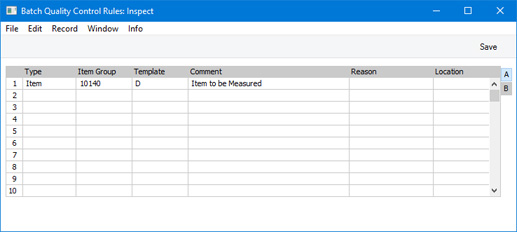

To work with Batch Quality Control Rules, first ensure you are in the Service Orders module. Then, if you are using Windows or Mac OS X, open the settings list by clicking the [Settings] button in the Navigation Centre or using the Ctrl-S/⌘-S keyboard shortcut and then double-click 'Batch Quality Control Rules' in the list. If you are using iOS or Android, select 'Settings' from the Tools menu (with 'wrench' icon) and tap 'Batch Quality Control Rules' in the 'Settings' list. The 'Batch Quality Control Rules: Inspect' window will be opened, showing any Rules that you have previously entered. Each row in the matrix contains a separate Batch Quality Control Rule.

To edit a Batch Quality Control Rule, simply click (Windows/Mac OS X) or tap (iOS/Android) in the field to be changed and overtype the existing entry. To add a new Batch Quality Control Rule, scroll down to the first blank line. If you are using iOS or Android, you can add rows by tapping the + button below the matrix. Click [Save] (Windows/Mac OS X) or tap √ (iOS/Android) in the Button Bar to save changes. To close the window without saving changes, use the close box (Windows/Mac OS X) or tap < (iOS/Android).

After entering a Goods Receipt, Production, Production Operation, Returned Goods record, Returned Goods to Supplier record, Stock Depreciation record or Stock Movement, you will be able to create Batch Quality Control records from the transaction for any of the Serial Numbers in the transaction. Each of these Batch Quality Control records will contain a Batch Quality Control Template, and the Tests included in the Template will be listed in the Batch Quality Control record. You can then enter the results of each Test as you carry them out. The Template in a new Batch Quality Control record will be chosen by checking the Batch Quality Control Rules setting for a row with the Item/Location/Register combination and taking the Template specified in that row.

When entering Batch Quality Control Rules, you should therefore ensure you enter a separate Rule (i.e. a separate row) for each Item/Location/Register. You can leave the Location and/or Register fields empty if the same Rule is to apply to every Location and/or Register.

The information required for each Batch Quality Control Rule record is as follows:

Flip A

- Type

- Paste Special

Choices of possible entries

- This field can contain one of two entries: "Item" or "Item Group". Use it to indicate whether the Item Group field immediately to the right contains or will contain an Item or an Item Group. Use 'Paste Special' to increase input speed.

- Item Group

- Paste Special

Item or Item Group registers

- Specify the Item or Item Group that is to be subject to the Tests contained in the Batch Quality Control Template that you specify to the right.

- If you enter an Item here, set the Row Type to "Item". If you enter an Item Group, set the Row Type to "Item Group". If you set the Row Type before entering an Item or Item Group, this will determine whether the 'Paste Special' window will list Items or Item Groups when you open it from this field.

- Template

- Paste Special

Batch Quality Control Templates setting, Service Orders module

- Choose a Batch Quality Control Template using 'Paste Special'.

- When you create a Batch Quality Control record from a Goods Receipt, Production, Production Operation, Returned Goods record, Returned Goods to Supplier record, Stock Depreciation record or Stock Movement, the Template specified in the row in this setting for the Item/Location/Register combination will be copied to the new Batch Quality Control record. The Tests in the Template will be copied to the Batch Quality Control record.

- Comment

- The Name or Description of the Item Group or Item that you specify in the field to the left will be brought in to this field automatically.

- Location

- Paste Special

Locations setting, Stock module

- If you need to apply a different Template of Tests to the Item or Item Group depending on the Location, enter separate rows with each Location specified in this field. You can also enter a row in which the Location field is blank, to act as the default. Alternatively, enter a single row with a blank Location if the same Template of Tests is to be used in every Location.

Flip B

- Register

- Paste Special

Choices of possible entries

- If you need a different Template of Tests to be copied to a Batch Quality Control record depending on the register from which you create that record, enter separate rows with each Register specified in this field. You can also enter a row in which the Register field is blank, to act as the default. Alternatively, enter a single row with a blank Register if the same Template is to be copied to every Batch Quality Control record.

- For example, you may need to carry out different sets of Tests when receiving an Item into stock for the first time and when receiving an Item back into stock that has been returned by a Customer. In this case, enter two rows for the same Item, one in which the Register is "Goods Receipts" and one in which the Register is "Return Goods". If you enter a third row for the Item in which the Register is blank, the Template in that row will be used in all other circumstances (i.e. when you create Batch Quality Control records from Productions, Production Operations, Stock Depreciations and Returned Goods to Supplier records).

After defining Batch Quality Control Rules, you will be able to enter Batch Quality Control records where you can enter the results of your quality control tests. Please refer to the next section for details.

---

Batch Quality Settings in Standard ERP:

Settings in the Service Orders module:

Go back to: